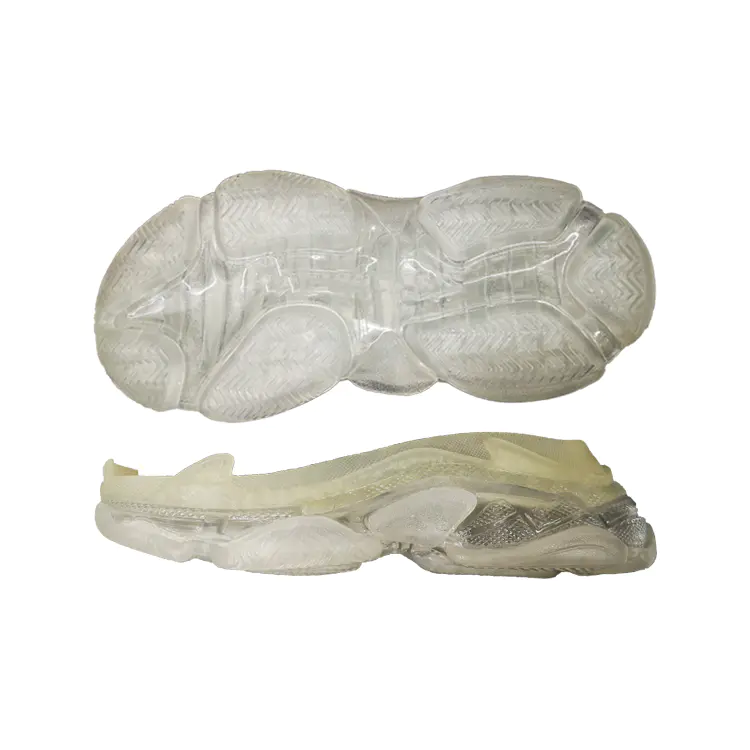

How did BEF design rubber sole sheet suppliers?

2020-12-22

The design process of rubber sole sheet suppliers can be finished through 4 steps. Concept developing and product design planning come first. Our designers and technicians work together for the expected product performance and appearance design. The detailed design process comes next. Based on the results of the discussion, our designers should consider the materials processing, target application fields, and user experience comprehensively when conducting the product design rather than focusing on the product shapes, colors, and specifications only. Then, designers will deliver the product drawings or sketches to every department of our company for feedback collecting. The last step is the final confirmation. After reaching a mutual agreement on the product design between customers and us, the product design process is finished and the sample will be made based on the design sketches.

GuangZhou BEF Shoes Material Co.,ltd is China's largest modern Rubber production base. According to the material, BEF's products are divided into several categories, and rubber sole material is one of them. The quality control of BEF safety shoe sole is conducted rigorously in order to meet the requirements in the solar product industry. It is inspected in the short circuit protection, charge and discharge performance, as well as energy utilization capacity. It promotes the even distribution of foot pressure. The product can help users avoid eye strain and headaches while improving overall mood. It also brings appropriate brightness for a specific space. Durability is a big selling point of this product.

Our purpose is: to exceed our customers’ expectations for service, quality, and value. Since this purpose has been settled down, we have strived to cultivate our customer service team, improve product quality and value. Please contact.

GuangZhou BEF Shoes Material Co.,ltd is China's largest modern Rubber production base. According to the material, BEF's products are divided into several categories, and rubber sole material is one of them. The quality control of BEF safety shoe sole is conducted rigorously in order to meet the requirements in the solar product industry. It is inspected in the short circuit protection, charge and discharge performance, as well as energy utilization capacity. It promotes the even distribution of foot pressure. The product can help users avoid eye strain and headaches while improving overall mood. It also brings appropriate brightness for a specific space. Durability is a big selling point of this product.

Our purpose is: to exceed our customers’ expectations for service, quality, and value. Since this purpose has been settled down, we have strived to cultivate our customer service team, improve product quality and value. Please contact.

Custom message