Company Advantages1. The material, production, design of custom made in

soles comply with international regulations. It is dirt-, scratch- and grime- resistant

2. One of the factors that BEF has developed more clients is the establishment a mature sales network. It creates the best fit and support during sugged or strenuous wear

3. The product offers a combination of cushioning and responsiveness. The cushioning spreads the load out across the foot to reduce the impact of landing, while the responsiveness facilitates bounce back effortlessly and quickly. It does not contain allergens and carcinogenic dyes

4. The product is characterized by its air permeability. A new type of waterproof fabric layer is added, helping absorb any foot sweat and moisture. Durability is a big selling point of this product

5. The product features an ergonomic design. The forefoot part is designed with softness and comfort, the arch part with enough support, and the rear part with excellent cushioning. It holds advantages such as good stiffness, good resilience, and cost-effectiveness

Product Specifications

Product Specifications

| Type | Soles |

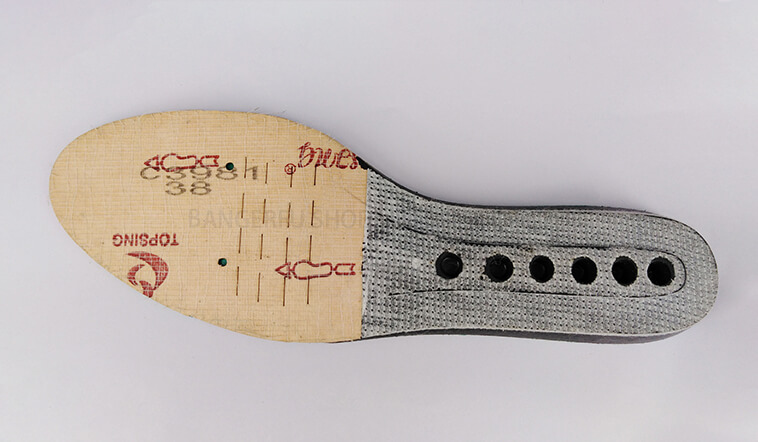

| Product Name | BEF Fashinableand new stype insoles single shoe 3981 |

| Size | Any To Your Request |

| Material | PP+ +steel supports+latex |

| Brand | OEM&ODM Are Both All Welcomed |

| Delivery Time | 10-40 Days After Samples &Deposit Confirmed |

| Color | Any To Your Request |

| Usable range | Woman's sandal or single shoe |

| Place of Origin | Guangzhou/china |

| Certificate | ISO 9001, ISO14001 , SATRA |

Product Features

Product Features

◪ 1.Using injection molding machine to shorten the process and reduce labor.

◪ 2.Specifications of the products and surface are unified.

◪ 3.Using New Type Insole of surface are more pleasing to the eye.

◪ 4.Using New Type Insole of high heels and thin heels walk more steadily.

Product Details

Product Details

NO.1

Green Latex Thickness :3mm

NO.3

Single hole steel core

Product Packing

Product Packing

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Company Features1. GuangZhou BEF Shoes Material Co.,ltd is a high-tech company that is oriented towardscustom made insoles industry. Scientific management and a strict quality assurance system have been formed in the BEF plant.

2. GuangZhou BEF Shoes Material Co.,ltd has a full set of advanced production and testing equipment.

3. By using advanced technology, GuangZhou BEF Shoes Material Co.,ltd has improved the not only the quality of high heel insoles but also its output. Based on the idea of thick insoles , BEF has always been standing at the strategic height to push forward implementation of the plans. Get info!

Product Specifications

Product Specifications

Product Features

Product Features

Product Details

Product Details

Product Packing

Product Packing