Product Specifications

Product Specifications

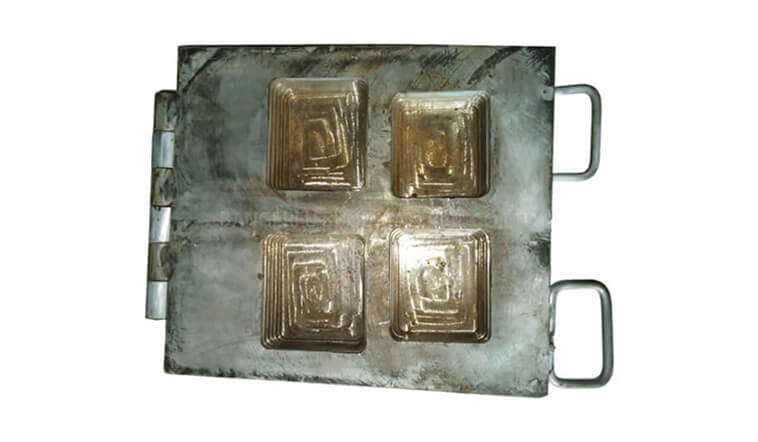

| Type | sole mould |

| Product Name | Custom men shoe sole mould for sneaker shoes |

| Model | Male shoe mold |

| Material | copper |

| Design | Twice-Mold-Opening |

| Size | 37-45 |

| Scope of application | Rubber sole |

| Brand | OEM&ODM Are Both All Welcomed |

| Delivery Time | 10-25 Days After Samples &Deposit Confirmed |

| Color | Silver |

| Specification | Customized and As your requirement |

| Mould life | 300,000-1,000,000 shoes |

| supply Ability | 200 Set/Sets per Month |

| Used machine | CNC, EDM Spark Machine, Milling Machine, etc |

| Place of Origin | Guangzhou/china |

Product Equipment

Product Equipment

◪ 1.Customer choose shoe items

◪ 2.Confirmation by buyer. Place the order and arrange deposit

◪ 3.Make design picture followed buyer's requirement

◪ 4.2D drawing and 3D drawings

◪ 5.Make 1:1 wooden mould (wooden dummy)

◪ 6.Customers approved the dummy

◪ 7.Making mould according to customers comments

◪ 8.3D mould adjustment

◪ 9.Making mould by fashioning

◪ 10.Precisr cast, Precise 3D scan and Reverse scan

◪ 11.CNC mould fashioning

◪ 12.Tongman combination

◪ 13.Try to the finished product

◪ 14.Customers confirmed the samples

◪ 15.Mould bebugging

◪ 16.Etching

◪ 17.Making approval sample

◪ 18.Customers confirmed the samples

◪ 19.Deal with mould surface

◪ 20.Delivery

Product Equipment

Product Equipment

Mold workshop;the company has 10 imported CNC, monthly production processing mold 200 pairs.

3D printing: the sole can be printed,and shoes can be made and tried on directly.

Product Details

Product Details

Product Packing

Product Packing

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2025 GuangZhou BEF Shoes Material Co.,Ltd. | All Rights Reserved Design by www.allweyes.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.