Product Specifications

Product Specifications

Product Features

Product Features

◪ 1.custom sizes according to your requirement.

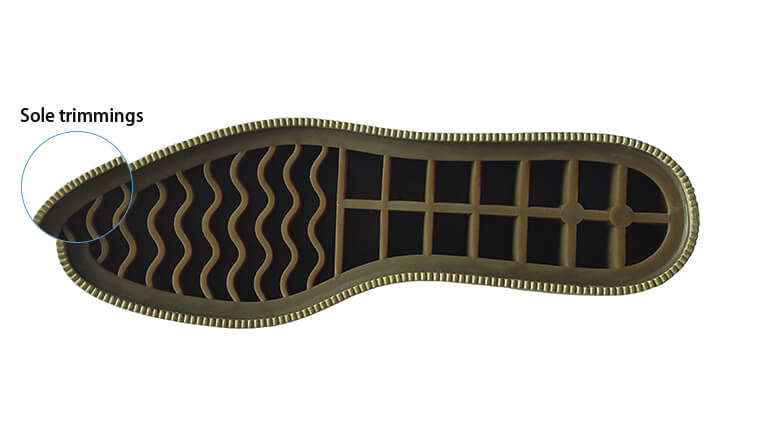

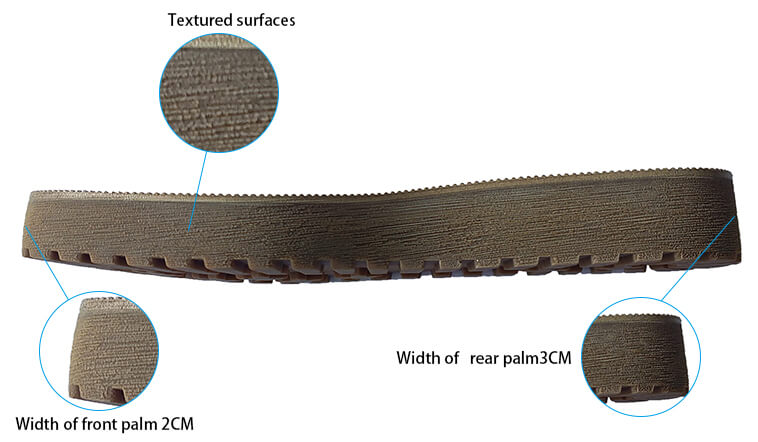

◪ 2.Rubber is used on the bottom layer to ensure the sole is wear-resistant and anti-skid.

◪ 3.The color is adjusted to suit your needs.

Product Details

Product Details

Product Packing

Product Packing

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2025 GuangZhou BEF Shoes Material Co.,Ltd. | All Rights Reserved Design by www.allweyes.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.