Product Specifications

Product Specifications

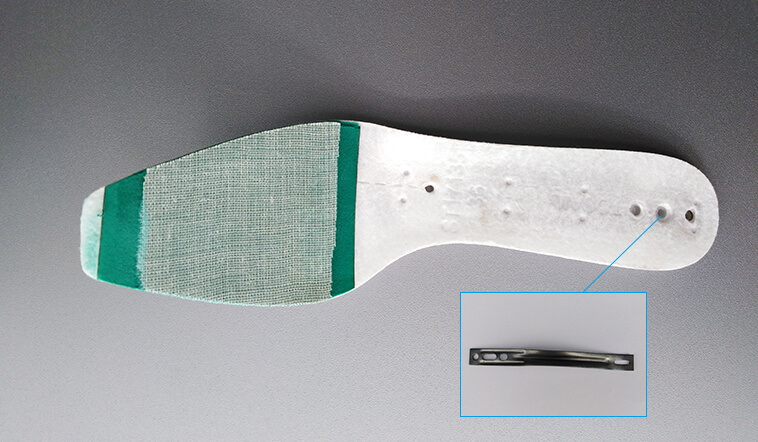

| Type | Soles |

| Product Name | BEF Fashinableand new stype insoles Spring shoes ST17135 |

| Size | Any To Your Request |

| Material | PP+ +steel supports+latex |

| Brand | OEM&ODM Are Both All Welcomed |

| Delivery Time | 10-40 Days After Samples &Deposit Confirmed |

| Color | Any To Your Request |

| Usable range | Woman's sandal or single shoe |

| Place of Origin | Guangzhou/china |

| Certificate | ISO 9001, ISO14001 , SATRA |

Product Features

Product Features

◪ 1.Using injection molding machine to shorten the process and reduce labor.

◪ 2.Specifications of the products and surface are unified.

◪ 3.Using New Type Insole of surface are more pleasing to the eye.

◪ 4.Using New Type Insole of high heels and thin heels walk more steadily.

Product Details

Product Details

Product Packing

Product Packing

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2025 GuangZhou BEF Shoes Material Co.,Ltd. | All Rights Reserved Design by www.allweyes.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.