Product Specifications

Product Specifications

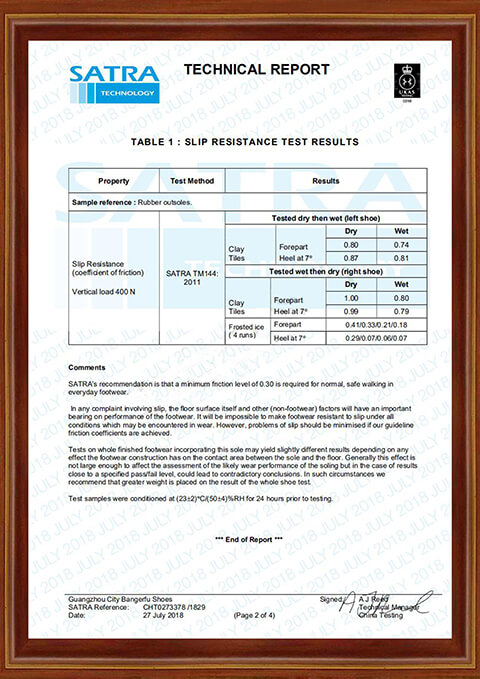

| Type | Slip resistance material |

| Product Name | I-Slip resistance material |

| Size | 310*115mm*1.5/2MM; 310*165mm*1.5/2MM |

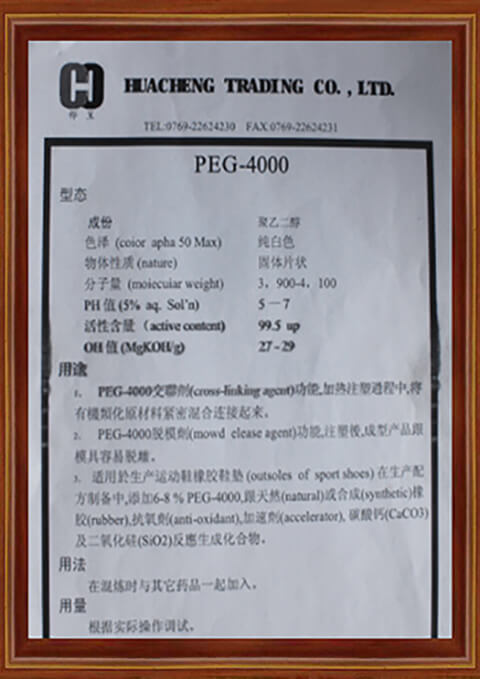

| Material | Rubber material |

| Brand | OEM&ODM Are Both All Welcomed |

| Delivery Time | 7-15 Days After Samples &Deposit Confirmed |

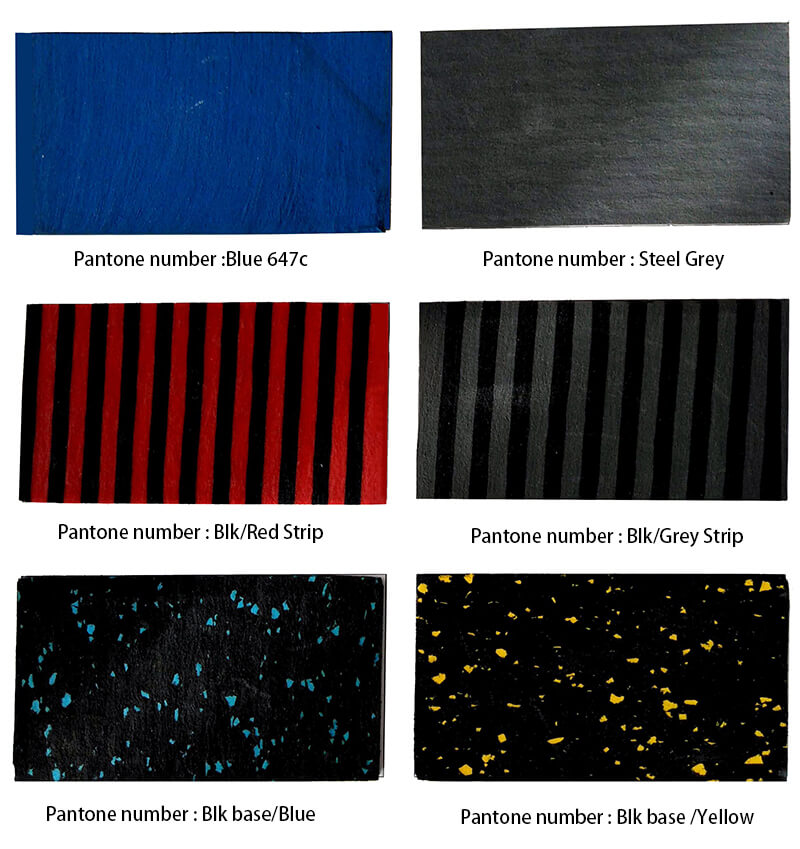

| Color | Any To Your Request |

| Usable range | Non - slip material can be used for soles, non - slip pads and other non - slip components |

| Place of Origin | Guangzhou/china |

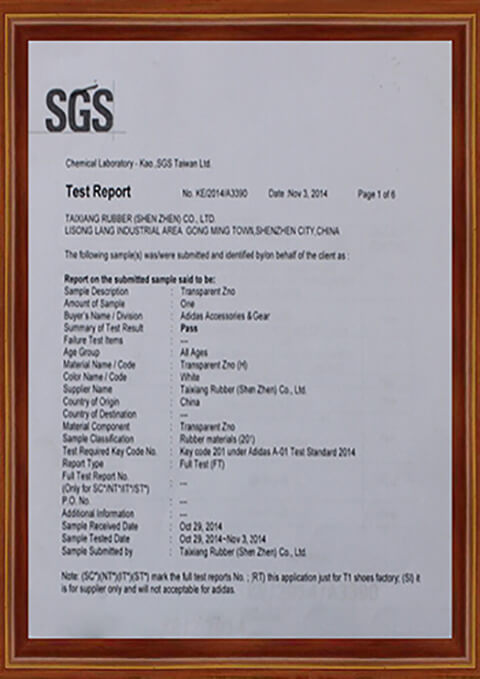

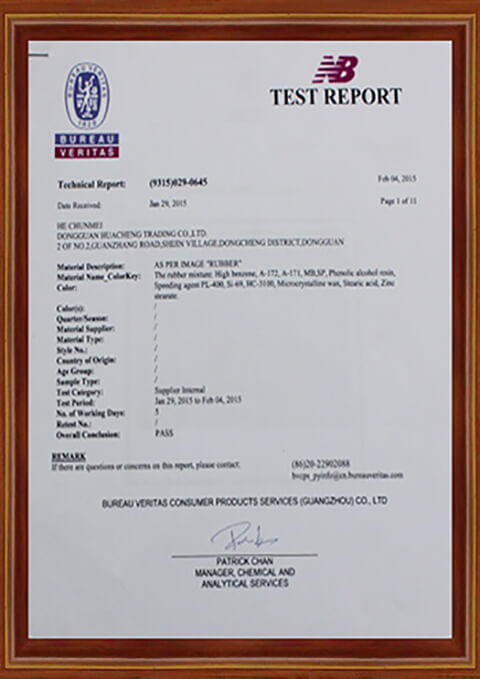

| Certificate | ISO 9001, ISO14001 , SATRA |

Rubber Material

Rubber Material

All matetial are with MSDS,RSL test report and technical specification.

All material should pass the European and USA environmental standards.

Product Features & Advantages

Product Features & Advantages

Advantage

◪ Compression Molding with rubber,reduce Laminating process.

Environment

◪ On marble, floor,slippery,oil-water, outdoor,, icy roads, the anti-slip effect is increased by 50% over traditional sole materials through real ice and STARA tests.

◪ It can be used for oil resistance, cold resistance, acid and alkali resistance, conductive and other special properties.

Features

◪ Old-resistant ,wear-resisting and physical property as rubber;

◪ It can be combined with RB, PU, EVA and TPR.

It is integrated with oil -water slip resistance material in the RB mould, no need for glue, pro-environment, and simplified production processes.

Application

Application

Formal shoe

Man's shoe

Outdoor‘s shoe

Sport's shoe

Ashional 's shoe

Old man or woman’s shoe

Test report

Test report

Color Card Number

Color Card Number

Partner Client

Partner Client

Product Packing

Product Packing

We support both OEM & ODM packaging. Our normally delivery method are by the sea, by air, by international express (DHL, UPS, TNT, FedEx)

Copyright © 2025 GuangZhou BEF Shoes Material Co.,Ltd. | All Rights Reserved Design by www.allweyes.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.